Tomato: the supply chain demands consistent products year-round

With the goal of generating greater demand for healthier, tastier, and higher-quality food throughout the entire fresh tomato supply chain, it is increasingly important to focus on high-tech horticulture. This is the case with the seed company Harmoniz, which continues to invest significantly in the professionalization and specialization of this sector.

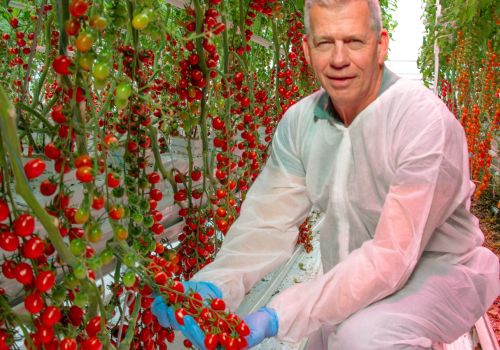

“In recent years, we’ve seen an increase in demand for products available throughout the year,” explains Wilfred Scheffers, Technical Sales Manager in the Netherlands. “Retailers want consistent products on the shelves 52 weeks in a year,” Scheffers emphasizes that “although producers are seeking for unique varieties to differentiate themselves in the market we can no longer afford to offer excellent products for only a few months of the year,” highlighting the importance of developing products with stable characteristics and consistent quality that can be grown in various production cycles and under different growing conditions.

Wilfred Scheffers, Technical Sales Manager in the Netherlands

Alongside this impressive cutting-edge facility in the Dutch Westland, Harmoniz is making significant investments in three additional locations—Canada, Mexico, and Italy—to validate the genetic material selected in the Netherlands. The company plans to carry out multiple trials in each region, to gain reliable information about the new hybrids potential and value for grower and consumers.

Grand Opening of PROOF R&D centre (Westland, NL)

“Adapting a variety for the high-tech market is anything but simple,” says Alessandra Francario, tomato breeder for Italy. “While it’s common to assume that hybrids tested in an active greenhouse will perform the same everywhere, each location highlights different strengths and weaknesses based on local climate conditions, growth cycles, and specific plant diseases.”

“This project has two main goals: to support the selection of high-tech hybrids in the Netherlands and to open new markets, such as northern Italy.” In Italy, trials are taking place in Ravenna at La Castellanina farm, where Francario works closely with Koen van der Knaap, head of tomato breeding for active greenhouses, and Wilfred Scheffers, conducting screenings and collecting qualitative and quantitative data on variety performance. “Studying the genetics of parental lines, starting from F1 hybrids, is key to creating new crosses with better quality and performance,” she adds.

Alessandra Francario, tomato breeder for Italy

“At the same time, these activities help us gather important insights beyond high-tech research. For example, we found that varieties resistant to ToBRFV are also heat-resistant, tolerating high temperatures conditions. Traits like these are highly valuable for all growers, who are increasingly facing climate challenges like higher temperatures and more frequent extreme weather, regardless of their cultivation methods.”

“Harmoniz is always striving to improve its services and products, aiming to enhance the year-round consumer experience while meeting the changing needs of growers,” Scheffers concludes. “The key to this success lies in our strong partnerships throughout the supply chain—a strategy we call the ‘downstream path.’ This approach helps us realize our vision: creating fresh products that consumers choose first and keep choosing over time.”